CHOOSING THE RIGHT METHOD FOR YOUR BUSINESS

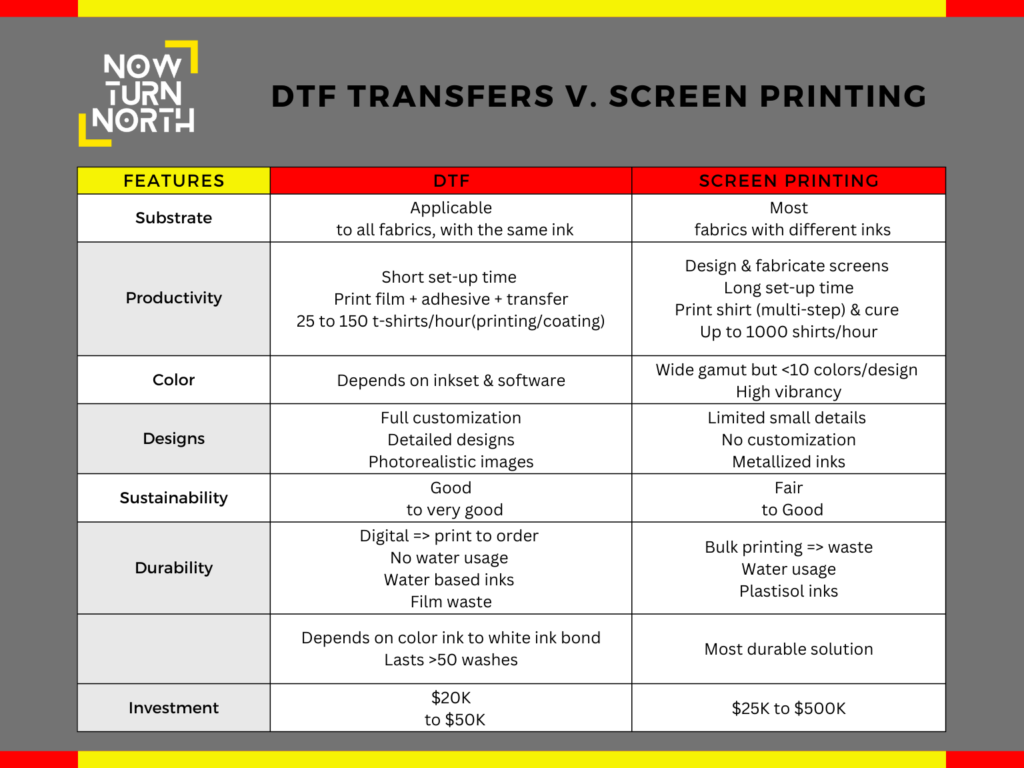

Selecting between traditional screen printing and the progressive Direct to Film (DTF) transfers presents a crucial choice for DIY enthusiasts. Screen printing is celebrated for its robustness and the ability to maintain color integrity across diverse fabrics, while DTF stands out with its streamlined production and minimized material excess. The decision transcends artistic expression, impacting the qualitative and fiscal aspects of your enterprise. This discourse will dissect both methods thoroughly. We will scrutinize screen printing’s methodical approach, necessitating a mesh screen for ink application, against DTF’s precision and chromatic vibrancy. By the close of this exploration, you will gain a comprehensive understanding of both processes, enabling a strategic choice that complements your artistic endeavors and business strategy. Let’s embark on a detailed comparison to discern which method will elevate your DIY creations to a level of professional excellence.

A QUICK GLIMPSE INTO THE PRINTING INDUSTRIES

For enterprises navigating the printing landscape, the selection of a printing technique is a strategic decision, deeply influencing profitability and client contentment. Delving into a business-centric analysis, we present a concise delineation contrasting DTF, traditional screen printing, and screen print transfers.

INTRO TO SCREEN PRINTING

Screen printing stands as a time-honored technique, deeply rooted in the fabric and design sectors for its adaptability and exceptional quality. Utilizing a mesh to transfer ink onto substrates with precision, it employs stencils to block ink from non-image areas. The application of each hue via separate screens cumulatively manifests the design’s full spectrum.

This printing method is especially beneficial for business startups, facilitating large-scale production at cost-effective rates post initial setup. The inks used for screen printing are celebrated for their depth of color and durability- ideal for striking designs that are crafted to last.

Entrepreneurially, screen printing represents a profitable venture, demanding initial investment but offering substantial returns through smart marketing, client education, and workflow refinement. Economies of scale achieved by bulk purchases and selecting cost-effective materials can significantly boost profit margins.

Ultimately, screen printing transcends its status as a mere technique, serving as a medium for artistic expression and a vessel for economic growth for the industrious learner.

INTRO TO DTF TRANSFERS

Direct to Film (DTF) printing is a transformative advance in the realm of printing technologies, tailor-made for the burgeoning custom apparel industry. This technique prints graphics onto specialized film before transferring them onto fabrics with heat and pressure. DTF stands out for its precision in rendering designs with striking detail and color intensity that are both durable and pliant.

DTF printing streamlines the multi-color printing process, eliminating the need for individual screens per color which screen printing necessitates. This efficiency extends to the capacity to print on various fabric colors without prior treatment, broadening the spectrum of materials suitable for embellishment. DTF’s print longevity rivals traditional methods, maintaining color fidelity and structural integrity through repeated laundering.

For business-minded individuals, DTF printing emerges as a financially viable and scalable option. The investment in DTF technology promises substantial returns with the production of superior, custom apparel catering to a wide-ranging customer base. Ideal for moderate production volumes, DTF offers a harmonious blend of high-grade output and operational efficiency, bypassing the extensive preparation associated with screen printing.

COST

In DIY printing, the balance between cost-efficiency and high-quality output is crucial. Cost analysis between screen printing and Direct to Film (DTF) printing reveals distinct considerations. Screen printing commands a higher initial investment due to the need for distinct screens for each color, driving up the complexity and cost for intricate designs. Additionally, it is labor-intensive, which can scale up the costs in high-volume productions.

In contrast, DTF printing presents a cost-effective alternative, particularly favorable for entry-level operations. Its digital nature significantly cuts down on manual labor, trimming labor costs accordingly. The absence of the need for multiple screens for multi-colored designs renders DTF economically advantageous for designs requiring a wide color palette. DTF is optimal for limited runs, enabling diverse and intricate designs without necessitating large quantities to offset the cost.

For small-scale DIY screen printers or newcomers, DTF printing emerges as a more accessible avenue, fostering both flexibility and innovation at a lower cost. Yet, for sizable orders with a uniform design, screen printing may be more cost-effective over time, benefiting from scale economies.

Deciding between screen printing and DTF printing requires assessing your production scale, design complexity, volume, and initial capital availability to determine the most financially prudent path.

DURABILITY

In the competitive space of print durability for revenue generation, screen printing is distinguished by its enduring quality. Properly cured screen-printed images penetrate deeply into the material, offering a defense against fading and cracking over time, a particular benefit on cotton fabrics. Renowned for its resilience through extensive washing and consistent use, this method has set the benchmark within the apparel sector for lasting wearability.

Direct to Film (DTF) printing, though a more recent advancement, similarly provides commendable durability. It involves transferring a printed design from film to fabric, creating a print that stands up well to pressure and flexing. Yet, when placed side by side with screen printing, DTF might not quite match up in terms of long-term endurance, sometimes exhibiting reduced fabric adhesion, which could impact its durability.

Entrepreneurs must weigh their options based on the product’s intended durability and usage. Screen printing emerges as the superior option for items subjected to rigorous wear. Conversely, for items with a shorter lifecycle or less intensive use, DTF presents an economical and proficient choice.

To sum up, screen printing and DTF printing each have their unique advantages, but for enduring quality, screen printing continues to lead, offering businesses a dependable option for durable printed goods.

EFFICIENCY

Efficiency in the print-for-profit sector encompasses more than just speed—it’s an aggregate of setup duration, expenditure, manpower, and swift fulfillment of client needs. Direct to Film (DTF) printing emerges as a paragon of efficiency, particularly beneficial for DIY screen printers aiming to amplify their profit generation.

DTF printing streamlines production by eliminating the intricate steps required in screen printing, such as the need for multiple screens for different colors. This reduction in both time and material expense is especially beneficial for limited runs or bespoke prints, where screen printing’s preparation could surpass the time spent on the actual print job.

Additionally, DTF’s capacity to render detailed and colorful designs directly onto film, later transferred to the fabric, offers a multipurpose solution suitable for a plethora of applications. This adaptability is vital for DIY printers who need to meet diverse customer requests without maintaining a large inventory or numerous pieces of equipment.

For screen printing entrepreneurs, operational scale is a decisive factor. While screen printing is more economical for bulk orders thanks to scale economies, DTF printing provides a strategic advantage for custom, small-scale jobs with its rapid production cycle and reduced initial costs. The efficiency of DTF printing can result in superior profit margins and a swift investment payback, positioning it as an appealing choice for those in the custom printing arena.

VERSILITY

Entrepreneurs and artisans looking to capitalize on their skills will find screen printing an incredibly versatile medium. Its historical resilience and compatibility with a plethora of materials, ranging from fabrics to metals, mark it as a formidable choice for myriad project types. Such flexibility forms the bedrock for enterprises aiming to serve a diverse customer base, facilitating expansion across various markets.

Direct to Film (DTF) printing emerges as a dynamic newcomer, swiftly becoming preferred for complex, color-rich designs. Its proficiency in executing intricate patterns and applying them uniformly to both light and dark textiles without multiple setups offers a marked benefit. This process is particularly advantageous for designs necessitating precision and vibrant hues, trends that are on the rise within the custom apparel sector.

Both screen and DTF printing possess distinct advantages that can be harnessed for revenue generation. The all-encompassing nature of screen printing invites a broad product range, while DTF’s adeptness in detailed graphics serves a specific segment that prizes intricacy and vividness in prints. Leveraging the strengths of each method allows entrepreneurs to forge a diversified and lucrative business structure tailored to their clientele’s diverse preferences.

AND THE DECISION GOES TO…

Concluding the comparison between screen printing and Direct to Film (DTF) for DIY screen printers, it’s clear that each technique has distinct strengths and profitability potential. Screen printing, with its legacy of durability, excels in large-scale production, proving to be cost-effective for bulk orders. Conversely, DTF printing shines in its agility, perfectly suited for limited runs and designs that demand precise detail. Your choice should be informed by your business’s unique requirements, including production volume, design intricacy, the lifespan of the product, and the amount of initial capital you are willing to invest.

At this juncture, it’s essential to reflect on more than just the technical specifications- envision the type of enterprise you aspire to establish. Whether your focus is on volume production or bespoke, intricate orders, or if you prefer the artisanship of traditional methods versus the innovation of modern technology, your responses will illuminate the path that best fits the business you envision.