TO PRINT OR TO STITCH: The Ultimate Showdown

In the dynamic world of personalized fashion, screen printing and embroidery stand out as two leading contenders. Each brings its own flair and functionality to the table, catering to diverse aesthetic and practical requirements. Understanding the distinct characteristics of screen printing and embroidery can guide you in choosing the method that aligns best with your style and purpose.

A BASIC RUNDOWN OF TWO DUELING CUSTOM APPAREL METHODS

Embroidery weaves elegance into fabric, using threads to intricately stitch designs. This method not only infuses a sophisticated touch but also ensures longevity and durability. Its versatility is unmatched, making it suitable for a variety of materials from classic cotton and denim to exquisite leather.

On the other side of the textile spectrum, screen printing is the art of pressing vivid inks through a stencil onto fabric. This method is a favorite for creating striking team uniforms and promotional items, particularly excelling with large, bold designs in radiant colors. While screen printing stands out for its cost-efficiency in mass production, its brilliance may diminish over time due to ink deterioration from washing or sunlight exposure.

When contemplating embroidery versus printing, the choice hinges on your vision and practicality. Opt for embroidery for a touch of luxury and endurance, or screen printing for expansive designs and quick, voluminous production. The type of fabric also plays a crucial role; screen printing is a match for cotton and wool, while embroidery adorns materials like leather and silk with finesse.

Direct-to-garment (DTG) printing offers another avenue, especially suited for detailed and complex images. While more costly than embroidery or screen printing, it excels in delivering sharp detail and vibrant color fidelity.

SCREEN PRINT vs. EMBROIDERY: Unraveling the Threads of Fashion

Delving into the realm of garment decoration, screen printing and embroidery emerge as two distinct yet popular techniques, each bringing unique attributes to the table.

Process and Technique

Screen printing involves a creative process of crafting a stencil for each color in your design. The stencil is placed on the garment, and then ink is skillfully spread over it with a squeegee, transferring the design onto the fabric in vibrant layers.

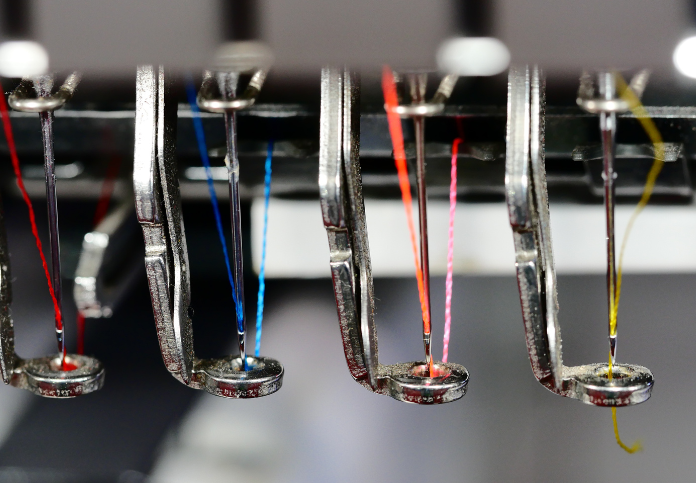

Embroidery, a craft of elegance, involves stitching your design directly onto the fabric. The design is first digitized, then meticulously brought to life by advanced embroidery machines, weaving the pattern into the fabric.

Design & Detail

Screen printing excels with large, bold color blocks and striking graphics, ideal for making a statement. However, it’s less suited for intricate designs, as the layered ink can create a slightly textured feel on the fabric.

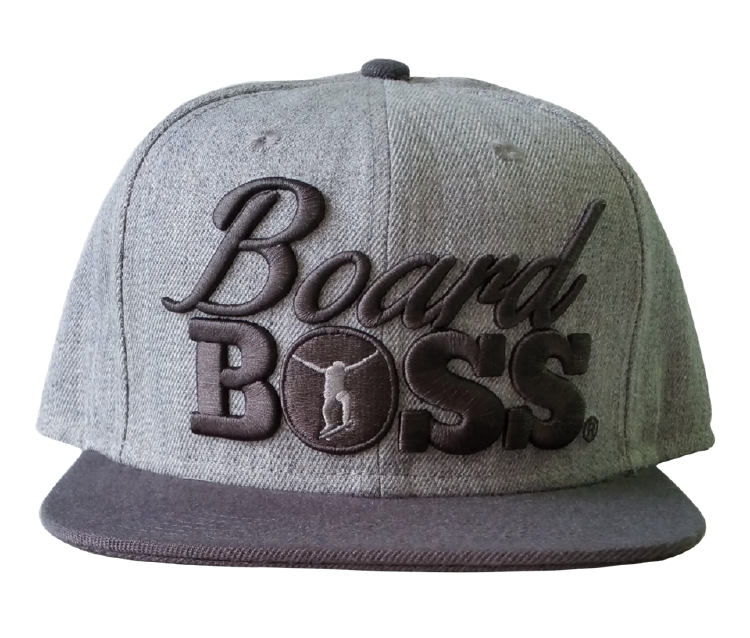

Embroidery is the go-to for detailed, smaller designs or text. It offers refined precision, adding a tactile depth and a raised 3D appearance to the fabric.

Durability

Screen printing may not rival the robustness of embroidery, as its ink can fade or crack over time with frequent washing. However, with proper care, these prints can maintain their allure for years.

Embroidery boasts remarkable durability, integrating the design into the fabric itself, making it resilient against regular wear and tear.

Cost Efficiency

For large orders, screen printing often comes out as the more economical choice, thanks to its quicker and simpler process.

Embroidery, while potentially pricier for bulk orders due to its intricate process, can be more cost-effective for smaller orders without the need for extensive setup.

Appropriate Usage

For a sophisticated look on business shirts or polos, embroidery is typically preferred. It adds a touch of class, especially on caps and outerwear.

Screen printing, on the other hand, is ideal for t-shirts and lightweight garments. It avoids the puckering that might occur with embroidery and provides a smoother finish for large designs.

Color Palette

Screen printing offers a kaleidoscope of color options, including bright neons and shimmering metallics, ensuring your design stands out.

Embroidery, though limited to thread colors, also offers a variety of hues. Advanced machines can blend different thread colors, though the range isn’t as extensive as in screen printing.

Size & Placement Flexibility

Screen printing shines when it comes to large designs, allowing for intricate detailing. However, capturing very small details can be challenging.

Embroidery excels in smaller, more precise designs. It also offers versatility in placement, adorning areas like sleeves, pockets, and collars, in contrast to the more typical locations for screen printing.

Texture & Feel

Screen printing results in a smooth, even finish on garments.

Meanwhile, embroidery adds a textured, raised feel. This difference can significantly influence the overall appearance and feel of the clothes.

Customization Potential

Screen printing is perfect for producing a series of garments with a consistent design, efficiently replicating the same image.

Embroidery allows for unique customizations on each piece, making it a popular choice for personalized items like hats and bags.

EMBROIDERY: Pros, Cons, & the Stitches in Between

Versatility

Embroidery offers a range of artistic techniques for enhancing t-shirt designs, including the subtle elegance of flat embroidery, dynamic puff embroidery, and the versatility of patches. Its ability to adapt to various fabrics makes it a go-to choice for diverse applications. For example, embroidery patches are a stylish addition to beanies and other headwear, while denim is transformed through the textural contrast of both flat and puff embroidery.

Durability

Embroidery, often chosen over screen printing, utilizes robust polyester threads capable of withstanding tough conditions typical in industrial environments, such as bleaching, extensive laundering, and intense friction. Its durability is so renowned that it’s even utilized for military uniforms.

Professional Appearance

Garments adorned with embroidery exude a refined and sophisticated look. This professional appearance makes embroidered items ideal for both marketing efforts and formal attire, frequently seen in corporate and military uniforms.

Cost Efficiency in Color Usage

In embroidery, the diversity of colors in your design doesn’t influence the project’s overall cost. Modern embroidery machines can incorporate up to 15 different thread colors, with pricing based on a flat rate per palette and stitch count, offering creative freedom in color choice.

Limitations in Color Gradients

Achieving smooth transitions between colors can be challenging in embroidery due to the lack of intermediate tones in threads, making them more suitable for designs with distinct color changes.

Incompatibility with Waterproof Fabrics

The needlework involved in embroidery can compromise the integrity of waterproof materials, creating punctures that allow moisture penetration. While still a favored choice for many, screen printing is recommended for waterproof garments.

Constraints in Small Text

When it comes to compact text, embroidery has its limitations. To ensure readability, the minimum height for embroidered text should be 0.25 inches. This consideration is crucial for effective logo scaling, particularly for placements like the left chest or caps.

SCREEN PRINTING: Advantages and Challenges

Ideal for Diverse Garment Types

The screen-printing process does not require needles, making it perfectly suited for lightweight and specialty garments such as hi-vis vests and waterproof jackets.

Precision in Small Text

When it comes to capturing fine details, screen printing excels, particularly with small text. This method bypasses the complications often encountered in embroidery for small-scale writing.

Mastery in Color Gradients

Screen printing allows for the creation of complex and detailed images, especially those with gradient colors. This technique can effortlessly bring to life designs featuring gradients like rainbows or intricate logos.

Ink Color Variations Based on Fabric

The ink color in screen printing can be influenced by the garment’s fabric and dye. For example, printing on a black shirt without a base layer can alter the ink’s appearance. The impact varies between natural fibers like cotton and synthetic materials like rayon and polyester, with the latter potentially affecting the print’s vibrancy. Screen printing professionals are adept at navigating these nuances to ensure optimal results.

Cost Fluctuations Based on Color Complexity

The number of colors in a design can affect the overall cost of screen printing due to the need for separate screens for each color. While this can limit those with tighter budgets, printing in large quantities of the same multi-color design can offer substantial savings.

Quantity Matters

Bulk orders with screen printing are cost-effective, as a single mesh screen can be utilized for multiple prints. This approach significantly reduces the cost of screen creation, distributing it across all printed items efficiently.

EMBROIDERY & SCREEN PRINTING: It’s Not a One-Size-Fits-All

When deciding whether to opt for embroidery or screen printing for your garments, it’s essential to consider your specific needs and preferences. Here’s a guide to help you make an informed decision:

Durability

If you’re looking for a decoration method that withstands multiple washes and wear, embroidery is the superior choice. The stitches are integrated into the fabric, enhancing the longevity of the design compared to screen printing.

Appearance and Texture

For a textured, three-dimensional look, embroidery is the go-to option. It adds a raised effect to the fabric, whereas screen printing results in a flat, smooth finish.

Customization

Embroidery offers greater flexibility for customization. Each piece of clothing can feature a unique name or emblem, making it perfect for personalized items. In contrast, screen printing requires a new screen for each color variation, limiting its versatility in customization.

THE FINAL DECISION: Navigating the Choice Between Screen Printing and Embroidery

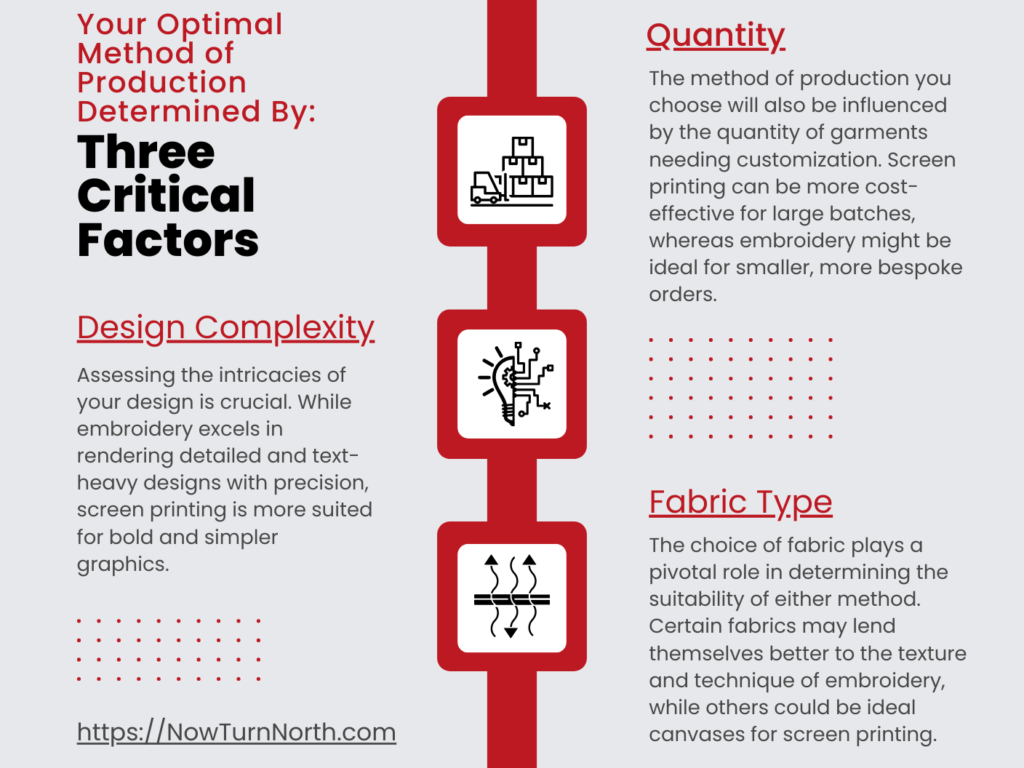

In the diverse world of garment customization, both screen printing and embroidery stand as prominent choices, each with its unique set of strengths and challenges. The optimal method for your project basically hinges on three critical factors; design complexity, quantity, and fabric style.

To ensure you make the best choice tailored to your specific needs, consider consulting with a seasoned garment printing expert. Their expertise can guide you in selecting between screen printing and embroidery, ensuring your designs are both aesthetically pleasing and functionally sound.